LiquidAider

Boulder's makerspace, Solid State Depot, hosts an open house every Tuesday evening. It encourages people to bring their projects and take advantage of the expertise of other members. One evening I met Matt Steele who had a rough prototype and a big vision for a wireless hydration system for Motocross racers. Over the next few years I helped him bring the vision to life with hardware, firmware and manufacturing test fixture design.

(Photos: LiquidAider)

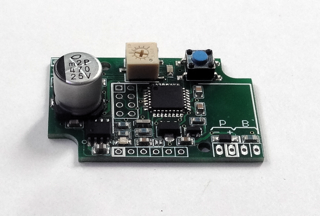

First Generation

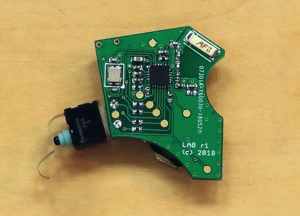

First generation of the system that Matt used to test his idea and get feedback.

- Prototypes used Arduino development environment so client could modify code if necessary.

- 2.4 GHz RF operation.

- Identical transmitter and receiver boards to simplify production.

- Automotive power-conditioning circuitry to handle reverse polarity spikes and high-voltage load-dump conditions.

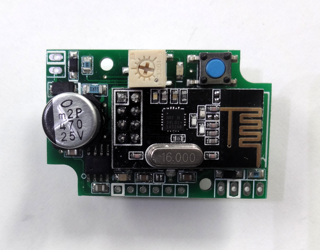

Second Generation

Feedback from the prototype system allowed design of the production system, based around the Nordic NRF24LE1 RF-SOC.

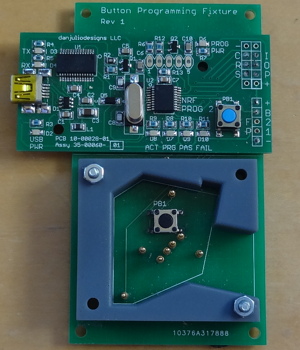

- Design (hardware, firmware) of an ultra-low-power button assembly running on a coin-cell and the pump controller that communicate using a two-way proprietary RF protocol designed for reliability and easy configuration.

- Battery testing and analysis.

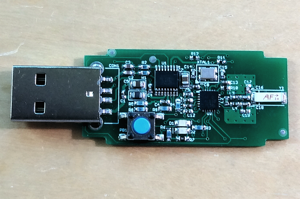

- Design several boards to support manufacturing including a USB Dongle, two programming boards and two functional test fixtures as well.

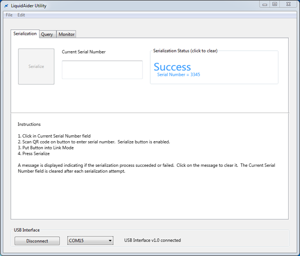

- Wrote an application for use serializing devices.

- Shepard devices through regulatory testing (FCC, UL, CE)