Impact Monitors

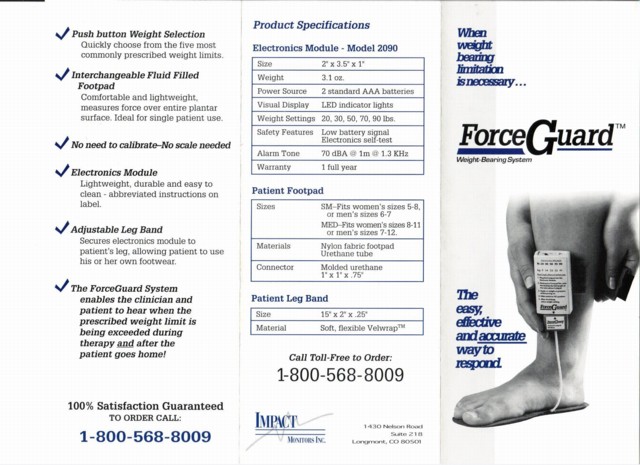

After Solbourne left the hardware business a couple of ex-Solbournites, Ty Sell and Mark Thomas, and I did some consulting before starting an engineering services company called Bolder Design Labs (BDL). We primarily provided ASIC verification services. While I had that gig going my wife had become involved with a small medical device start-up. I ended up helping them design a product for use in limited weight bearing regimens called the ForceGuard. It used a very simple PIC microcontroller and some analog electronics to measure the pressure exerted on a cleverly designed in-shoe footpad filled with Fluorinert (the stuff used to cool the Cray-2 and also used in the simulated liquid breathing system in the movie "The Abyss").

Although the firmware was fairly simple (about 4 Kbytes) it had to get FDA approval as a class II medical device. Lots of records, module-level testing and system testing. It actually made me think about the process of software development like never before. The firmware was a big state machine so I could avoid using interrupts but still keep up with the real time activities using a very slow processor clock (32 kHz / 8192 instructions/second). The device would run months or years on a set of batteries. I enjoyed working with my wife and we did really well together. It was a pretty big load doing this project as well as my full-time work at BDL.

Although the firmware was fairly simple (about 4 Kbytes) it had to get FDA approval as a class II medical device. Lots of records, module-level testing and system testing. It actually made me think about the process of software development like never before. The firmware was a big state machine so I could avoid using interrupts but still keep up with the real time activities using a very slow processor clock (32 kHz / 8192 instructions/second). The device would run months or years on a set of batteries. I enjoyed working with my wife and we did really well together. It was a pretty big load doing this project as well as my full-time work at BDL.

The wire was added to force the PIC into reset as the unit was switched off to prevent errant writes to an EEPROM.